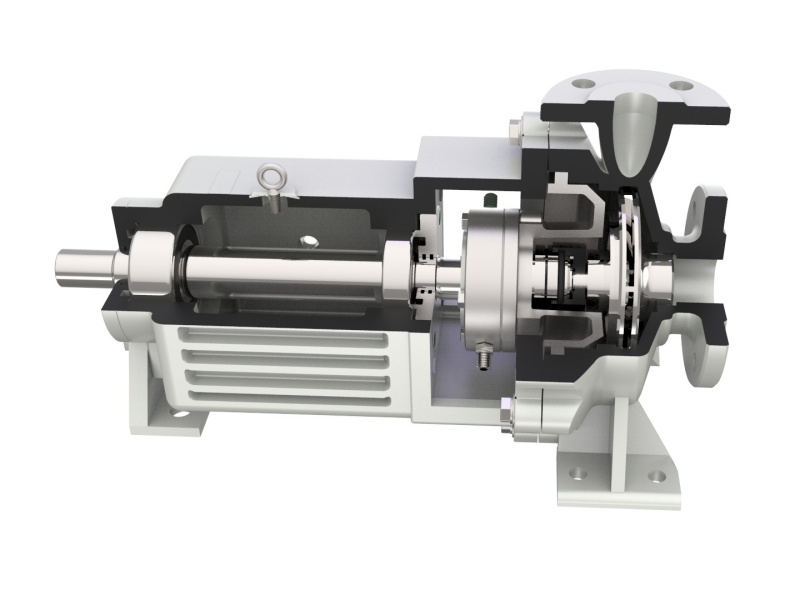

The working principle of a chemical centrifugal pump involves the conversion of mechanical energy into kinetic energy to move fluids. Here's a brief overview:

1. Impeller Rotation: The pump's impeller, driven by a motor, rotates at high speed. As it spins, it imparts kinetic energy to the fluid.

2. Centrifugal Force: The rotation creates centrifugal force, which pushes the fluid outward from the center of the impeller to the edges.

3. Fluid Movement: The fluid is then directed into the pump's volute casing, where its velocity decreases, and its pressure increases.

4. Discharge: The high-pressure fluid is discharged through the pump's outlet, allowing it to be transported through the piping system.

5. Suction: As the fluid is discharged, a low-pressure area is created at the impeller's center, drawing more fluid into the pump through the inlet.

This continuous process enables the efficient movement of fluids, making centrifugal pumps essential in various chemical processing applications.