TY series stainless steel submersible pump. Stainless steel construction, corrosion - proof. High performance, reliable for liquid transfer in different applications.

MOQ:

1Package:

CustomziedColor:

CustomziedMaterial:

SteelWorking Temp:

Fluoroplastic material:-20 to 200 ℃; Engineering plastic material:-20 to 80 ℃ ;Stainless steel material:-20 to 200 ℃ .Working Pressure:

1.6 MPa

Product review

TY submerged pump is designed in accordance with national standards . According to the working conditions of users , the submerged depth ranges from 1 to 8 meters . The main part of the pump is placed in the liquid . It has the advantages of wide corrosion resistance range , high efficiency , safe and reliable shaft connection structure , convenient disassembly and so on . It can be pumped without filling liquid . Because the axial force and radial force generated by the pump operation are supported by rolling bearings and sliding bearings respectively , it runs quietly and without noise.

Product advantages

1.Flow passage components such as pump casing, pump cover and impeller are made of high-quality stainless steel,fluoroplastic and engineering plastic;

2.There is no shaft seal,and the bearing and shaft sleeve are made of graphite,tetrafluoro and other materials to effectively ensure the service life of the pump;

3.It can be pumped without liquid filling,the depth under the liquid can reach 8m,and there is no need for independent lubrication and cooling water,which reduces the energy consumption.

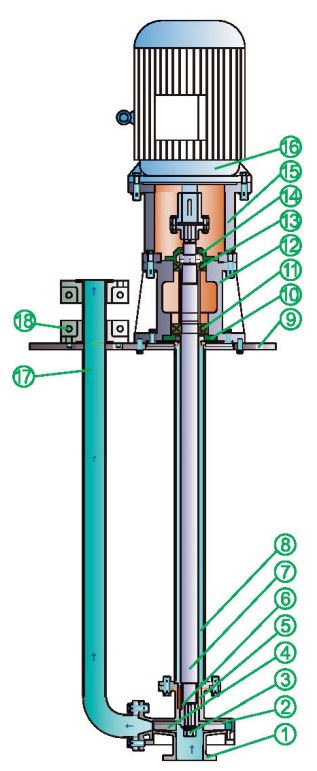

Material List

| Part | Material | Part | Material |

| ① Pump casing | 304/316/316L | ⑩ Front gland of bearing | HT200 |

| ② Pump cover | 304/316/316L | ⑪ Front bearing | Gcr15 |

| ③ Impeller nut | 304/316/316L | ⑫ Bearing box | HT200 |

| ④ Impeller | 304/316/316L | ⑬ Back bearing | Gcr15 |

| ⑤ Shaft sleeve | GRAPHITE/SIC | ⑭ Back gland of bearing | HT200 |

| ⑥ liner bushing | PTFE | ⑮ Bracket | HT200 |

| ⑦ Main shaft | 304/316/316L | ⑯ Motor | Customized |

| ⑧ Main pipeline | 304/316/316L | ⑰ Drainpipe | 304/316/316L |

| ⑨ Square plate | A3 | ⑱ Outlet flange | HT200 |

Structural diagram

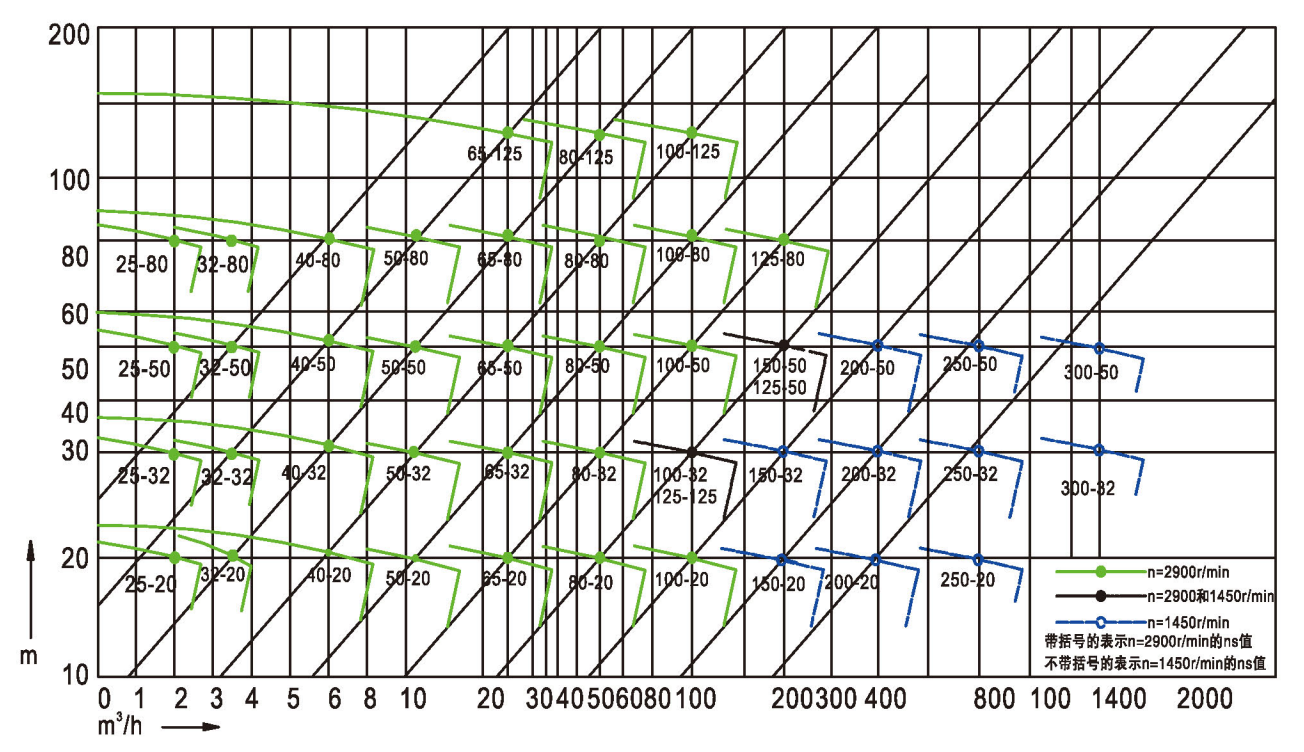

Performance range

Design pressure :1.6MPa; Flow :1.5~1000m³/h; Lift :15~125m; Power :2.2~185kw.

Applicable temperature : ① Ofluoroplastic material :-20~120℃( acid-base medium of any concentration );

② Engineering plastic material :-20~80℃( dilute acid and alkali medium );

③ Stainless steel material :-20~200℃( alkali medium ).

Product application

Widely used in petroleum, chemical industry,alkali making,smelting,rare earth, pesticide, dye, medicine, papermaking, electroplating, electrolysis, radio and other production processes to transport strong corrosive liquids.

Others