The TCA/E no - leakage petrochemical magnetic pump is designed for petrochemical use. It features no leakage, ensuring safety. High - quality materials and advanced technology make it reliable. Compact in size, it is easy to install and maintain, providing efficient fluid transfer in the harsh petrochemical environment.

MOQ:

1Package:

CustomziedColor:

CustomziedMaterial:

SteelWorking Temp:

-60 to 300 ℃,New material withstands temperatures up to 450°CWorking Pressure:

2.5 to 5.0 Mpa

Product overview

TCA series leakage free magnetic drive centrifugal chemical process pump is a world leading high - tech product developed by introducing German technology in accordance with API 685-2000sealless centrifugal pump for petroleum , heavy chemical and natural gas industry .

Product advantages

1. Pump material :304,316,904L,dual phase steel,Titanium alloy , Hastelloy ,etc.

2. Manufacturing standard : in accordance with Api685-2000 standard production, TCA foot support and TCE center support.

3. The magnet is a new type of permanent magnet with good magnetism,high temperature resistance and no demagnetization.

4. The shaft sleeve and sliding bearing adopt high wear - resistant silicon carbide ( SSIC ) and are equipped with lubrication grooves to effectively ensure the service life of the pump.

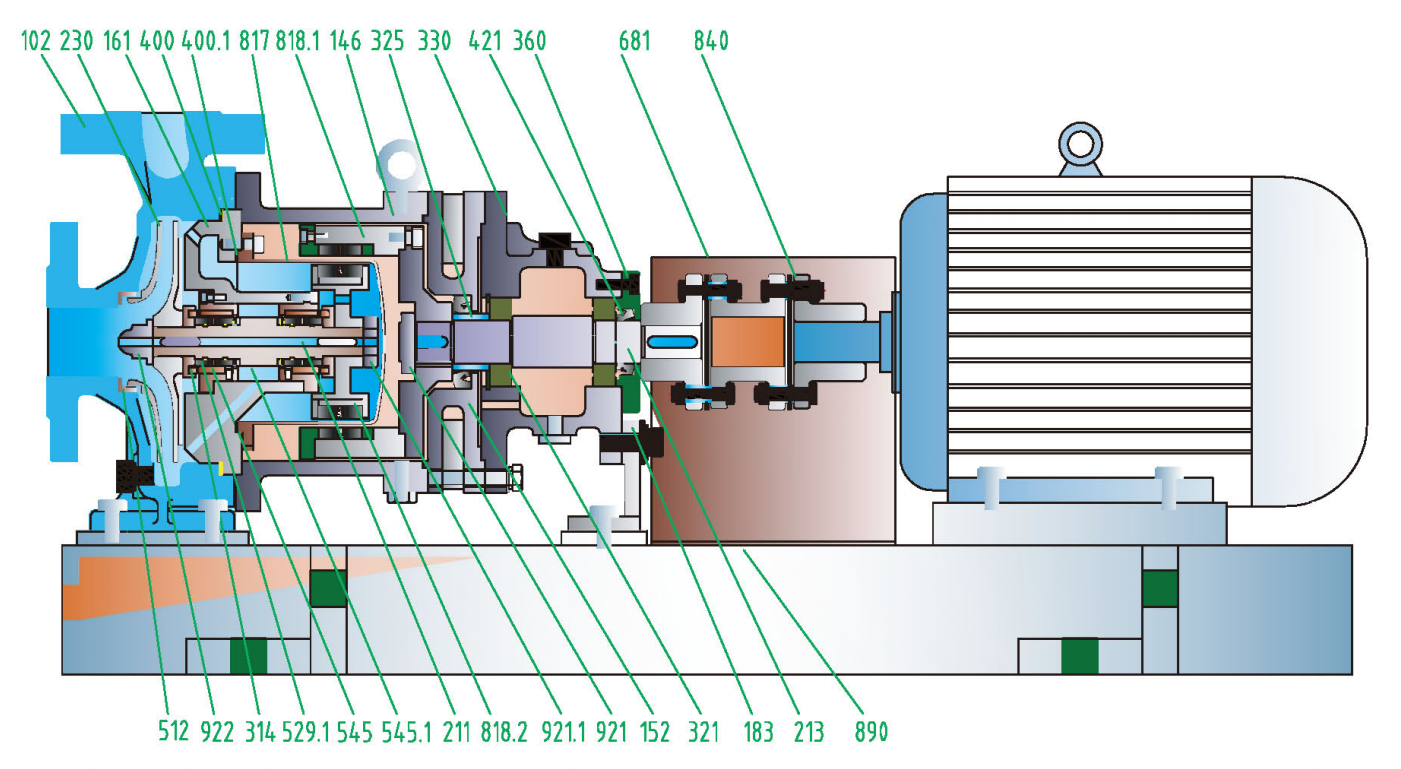

Material List

| Part | Material | Part | Material | Part | Material |

| 102 Pump body | 304/316/316L | 545.1 Bearing bushing | 304/316/316L | 545 Slide bearing | SSic/hard alloy |

| 230 Impeller | 304/316/316L | 890 Base plate | HT200/45 | 529.1 Bearing sleeve | SSic/hard alloy |

| 161 Pump cover | 304/316/316L | 213 Driven plate | 2Cr13 | 314 Thrust collar | SSic/hard alloy |

| 817 Distance sleeve | 316L/TA2/HC276 | 183 Bracket plate | HT 200 | 922 Impeller nut | 304/316/316L |

| 818.1 Outer magnet component | Permenant magnet/ZG | 152 Cooling bracket | 45 | 512 Wearing ring | 304/316/316L |

| 146 Bracket | HT 200 | 921 Locknut | 45 | 321 Ball bearing | Gcr15 |

| 330 Bearing box | HT 200 | 921.1 Locknut | 304/316/316L | 525 Bearing bushing | 45 |

| 360 Bearing gland | HT 200 | 818.2 Rotor assembly | Permenant magnet/304/316/316L | 400 Sealing gasket | PTFE |

| 681 Shield | 45/Aluminium | 211 Pump shaft | 304/316/316L | 400.1 Sealing gasket | PTFE |

| 840 Coupling | HT200/45 | 421 Oil seal | Fluorubber |

Structural diagram

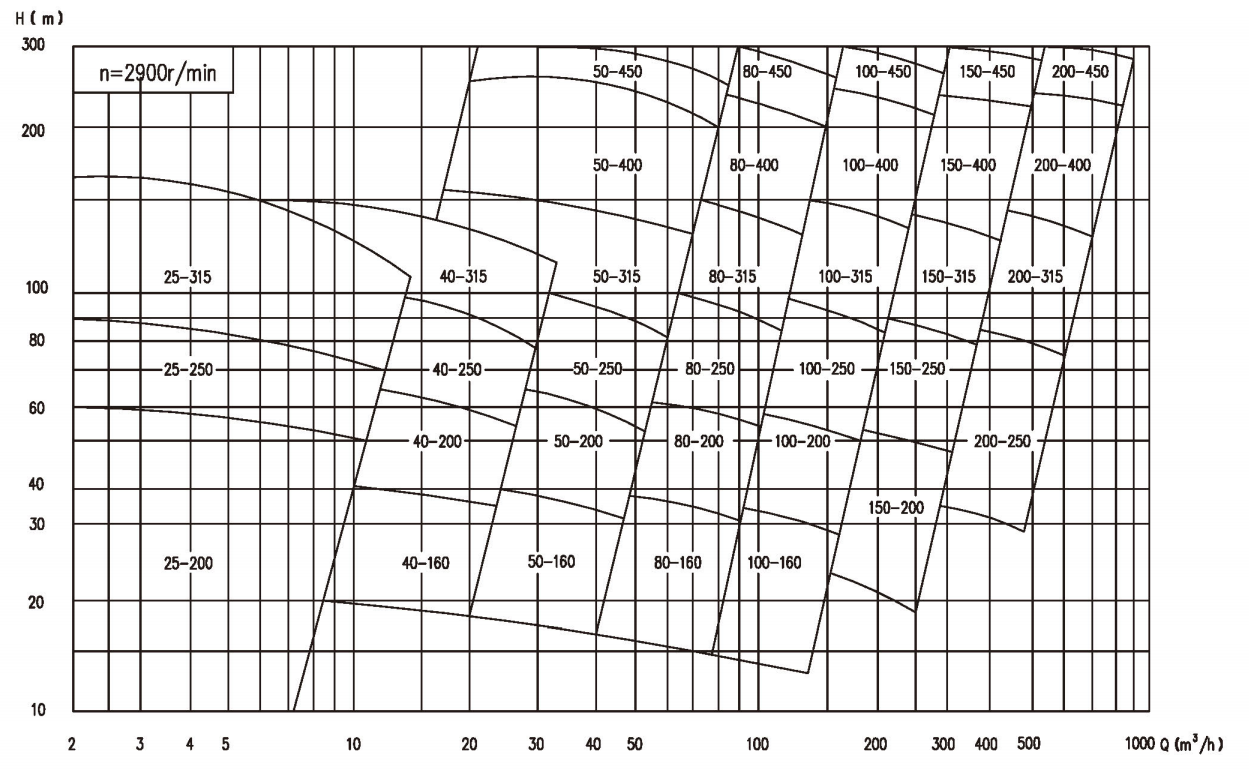

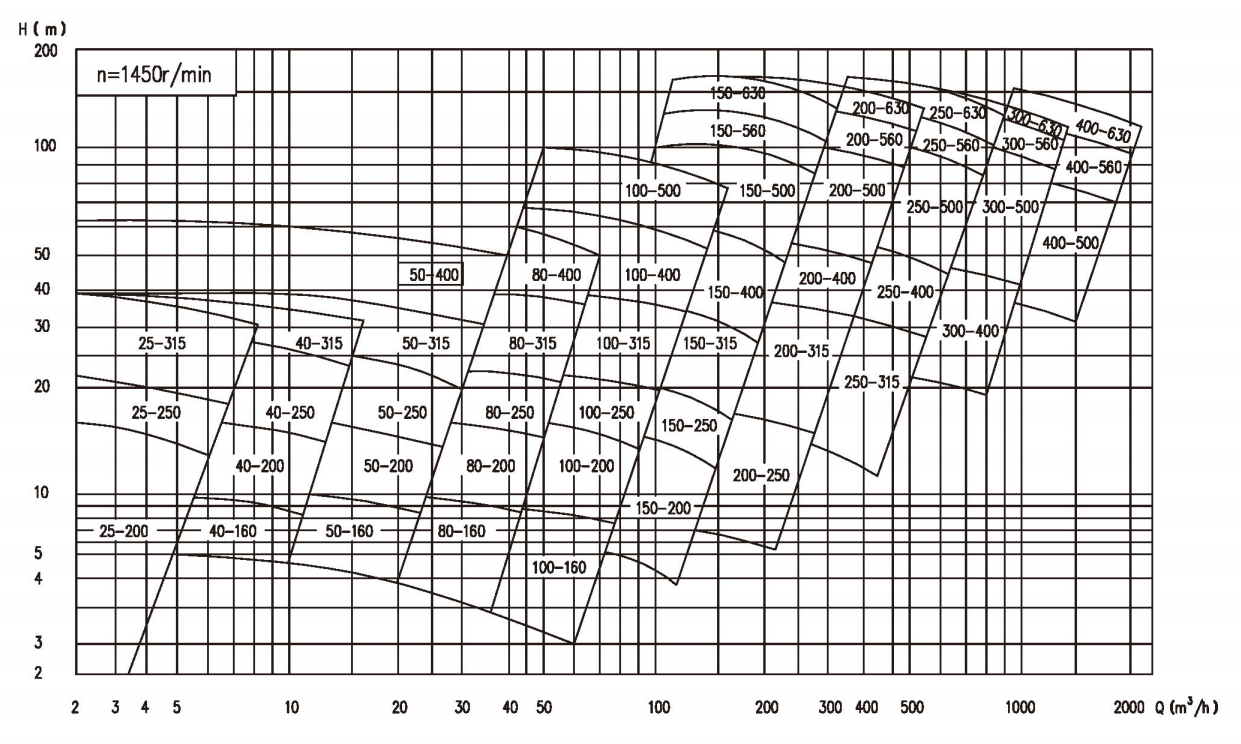

Performance range

Design pressure :2.5~5.0MPa, Flow :5.5~1900m³/h, Lift :16~250m, Power :2.2~500kw.

Applicable temperature :-60~300℃, new materials are adopted , and the temperature resistance can reach 450℃.

Product application

It can be widely used for production process transportation in chemical , petrochemical , pharmaceutical , printing and dyeing and other fields , especially for the transportation of flammable , explosive , toxic , harmful , corrosive and valuable liquid media.

Others