The TCD no - leakage multistage magnetic pump. With multistage structure, it can generate high pressure. The magnetic coupling guarantees no leakage, making it perfect for precise fluid handling in many fields.

MOQ:

1Package:

CustomziedColor:

CustomziedMaterial:

SteelWorking Temp:

-60 to 300 ℃,New material withstands temperatures up to 450°CWorking Pressure:

1.6 to 6.3 MPa

Product overview

TCD leak free multistage magnetic pump is designed by our company to solve the problem of fluid transportation with small flow and high head . Its structure , hydraulic and magnetic circuit design adopts advanced and novel technology , and the magnetic drive technology is successfully applied to the multistage magnetic centrifugal pump , which solves the problems of axial force balance and static sealing of multistage pump under high power , large gap magnetic circuit design and high working pressure .

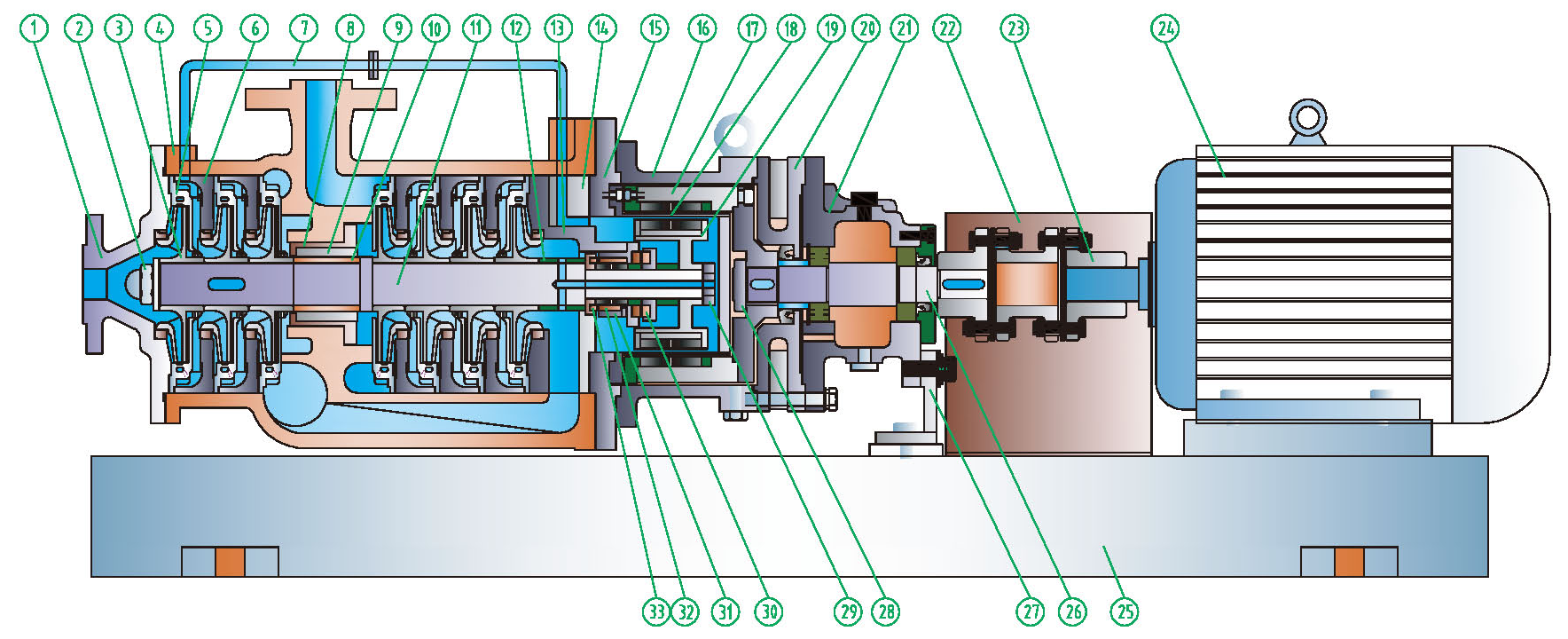

Material List

| Part | Material | Part | Material | Part | Material |

| ① Front cover | 304/316/316L | ⑫ Baffle sleeve | 304/316/316L | ㉓ Coupling | HT200 |

| ② Impeller nut | 304/316/316L | ⑬ Middle cover plate | 304/316/316L | ㉔ Motor | Per clients requested |

| ③ Impeller | 304/316/316L | ⑭ Back cover plate | 304/316/316L | ㉕ Base plate | HT200 |

| ④ Pump body | 304/316/316L | ⑮ Middle flange | 304/316/316L | ㉖ Drive shaft | 2CR13 |

| ⑤ Guide vane | 304/316/316L | ⑯ Bracket | HT200 | ㉗ Bracket plate | HT200 |

| ⑥ Middle | 304/316/316L | ⑰ Outer magnet component | Permenant magnet/ZG | ㉘ Round nut | 45 |

| ⑦ Return line | 304/316/316L | ⑱ Distance sleeve | 316/316L | ㉙ Rotor nut | 304/316/316L |

| ⑧ Front bearing seat | 304/316/316L | ⑲ Rotor component |

Permenant magnet /304/316/316L |

㉚ Back thrust collar | SSIC/hard alloy |

| ⑨ Front bearing | SSIC/hard alloy | ⑳ Bracket | 45 | ㉛ Back bearing | SSIC/hard alloy |

| ⑩ Front bearing sleeve | SSIC/hard alloy | ㉑ Bearing box | HT200 | ㉜ Back bearing sleeve | SSIC/hard alloy |

| ⑪ Pump shaft | 304/316/316L | ㉒ Shield | 202 | ㉝ Front thrust collar | SSIC/hard alloy |

Structural diagram

Performance range

Design pressure :1.6~6.3MPa, Flow :3~155m³/h, Lift :20~603m, Power :5.5~315KW.

Applicable temperature :-60~300℃, new materials are adopted , and the temperature resistance can reach 450℃.

Product application

Widely used in petroleum,chemical industry,acid making,alkali making,smelting,rare earth, pesticide, dye, medicine, papermaking, electroplating, electrolysis, pickling and other production processes to transport corrosive liquids.

Others