The TYC no - leakage double - shell magnetic submerged pump. It features a double - shell design for enhanced safety. Magnetic drive ensures no leakage. High - quality materials guarantee durability. Efficient operation meets various fluid transfer needs.

MOQ:

1Package:

CustomziedColor:

CustomziedMaterial:

SteelWorking Temp:

-20 to 350 ℃Working Pressure:

1.6 to 5 MPa

Product overview

TYC no leakage magnetic drive submerged pump is a pump type of submerged structure designed for the applicable occasions where the medium is required to be completely closed to prevent leakage during transportation . The submerged part that contacts the liquid is all made of stainless steel , and the submerged depth ranges from 1 to 6 meters . The main part of the pump is all placed in the liquid , which adopts static seal design . There is no traditional mechanical seal , and the medium can be completely isolated from the external air to truly achieve no leakage .

Product advantages

1. TYC no leakage magnetic drive submerged pump is a new type of efficient and energy - saving leak free submerged centrifugal pump designed according to national standards;

2. Flow passage components such as pump body , inner rotor , pump cover , impeller , isolation sleeve and pump shaft can be made of 304,316,316L,904,TA2,HC276 and other materials;

3. The pump body and pump cover adopt CFD computer fluid mechanics design hydraulic components for module design and precision casting , which has high cavitation resistance , smooth flow channel , and ensures the corrosion resistance and pressure resistance of the pump.

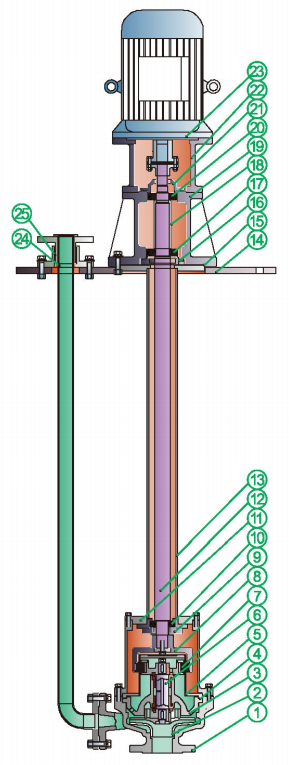

Material List

| Part | Material | Part | Material |

| ① Pump body | 304/316/316L | ⑭ Square plate | A3 |

| ② Impeller | 304/316/316L | ⑮ Sseal ring | Tetrafluoro |

| ③ Pump cover | 304/316/316L | ⑯ Bearing cover | HT200 |

| ④ Seal ring | Tetrafluoro | ⑰ Bearing | Rolling bearing |

| ⑤ Spacer sleeve | 304/316/316L | ⑱ Bearing retainer | 45# |

| ⑥ Minor axis | 304/316/316L | ⑲ Bearing housing | HT200 |

| ⑦ Inner rotor assembly | 304/316/316L/Permanent magnet | ⑳ Bearing | Rolling bearing |

| ⑧ Outer rotor assembly | 304/316/316L/Permanent magnet | ㉑ Bearing cover | HT200 |

| ⑨ Bearing cover | HT200 | ㉒ Bracket | HT200 |

| ⑩ Bearing | Rolling bearing | ㉓ Electric machinery | Per clients requested |

| ⑪ Bracket assembly | HT200/45# | ㉔ Outlet pipe | 304/316/316L/Pemanent magnet |

| ⑫ Principal axis | 2Cr13 | ㉕ Outlet flange | HT200 |

| ⑬ Executive director | 304/316/316L |

Structural diagram

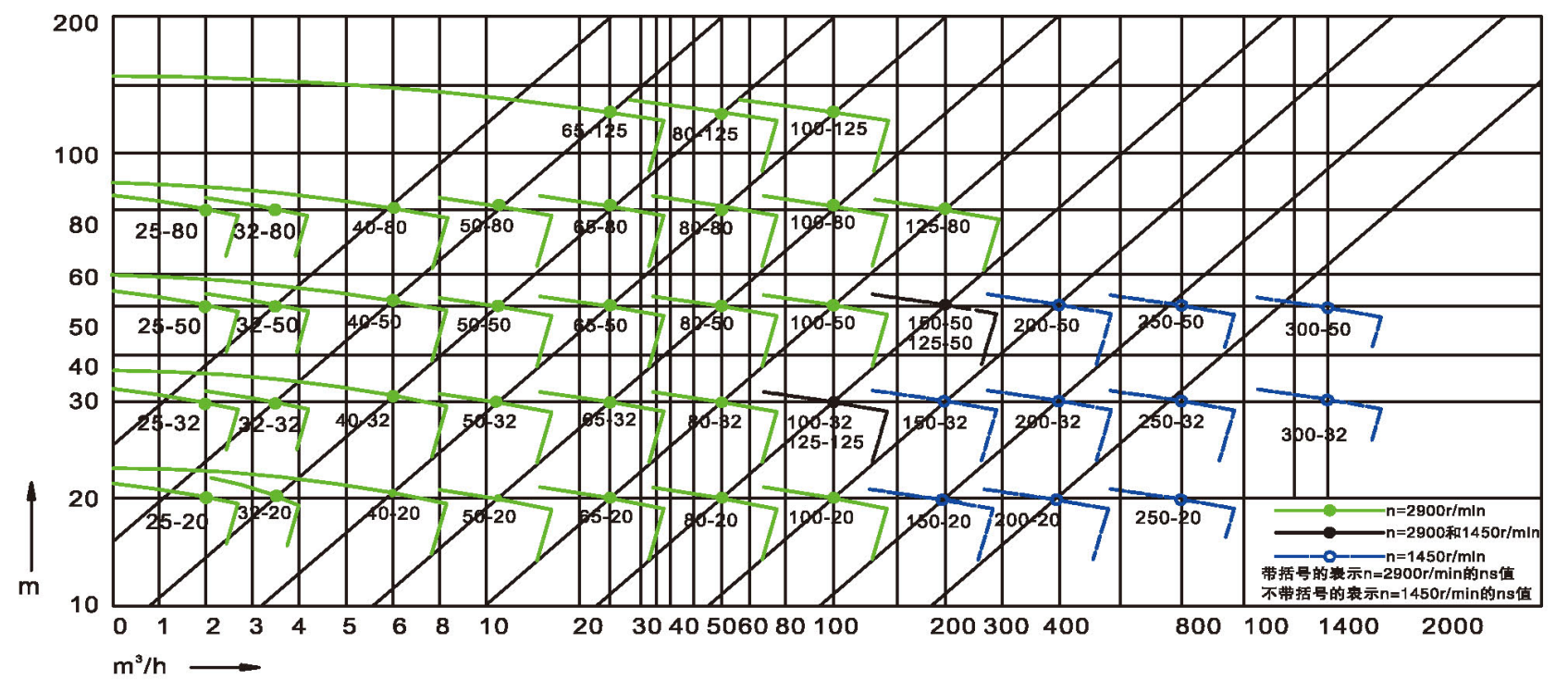

Performance range

Design pressure :1.6~5.0Mpa; Flow :1.8~400m2/h; Lift :15~125m; Power :1.5~280kw;

Applicable temperature :-20~350℃.

Product application

It is widely used in the transportation of volatile , flammable , explosive , toxic , harmful and other high - risk media in the production processes of petroleum , chemical industry , coalification , alkali making , smelting , rare earth , pesticides , dyes , medicine , scientific research institutions , national defense industry , etc.

Others