A magnetic pump is a new - generation centrifugal pump. It consists of the pump, magnetic actuator, and motor. Magnetic force transfers torque, eliminating leaks. It's corrosion - resistant, suitable for various industries like chemical and pharmaceutical.

MOQ:

1Package:

CustomziedColor:

CustomizedMaterial:

SteelWorking Temp:

-60 to 300 ℃Working Pressure:

1.6 to 6.3 MPa

Product review

The leakless magnetic pump is a new type of pump that uses the principle of modern magnetomechanics, according to GB / T25140-2010 technical conditions for shaftless rotary power pump (class II), which satisfies 15783-2002 technical specification for shaftless rotary power pump (class II), and with reference to API 685-20 leakless centrifugal pump for petroleum, heavy chemical and other media, and uses the magnetic drive of permanent magnet to achieve contactless transmission of torque. Because the medium is enclosed in the static isolation sleeve, the purpose of pumping the medium without leakage is achieved, and the problem of shaft seal leakage of mechanical drive pump is completely solved.

Product advantages

1.The magnet adopts ferrite magnet, Nd-Fe-B and samarium cobalt, which has good magnetism, high temperature resistance and no demagnetization;

2. The shaft sleeve and sliding bearing are made of high wear-resistant silicon carbide, graphite, tetrafluoro and other materials, and equipped with lubrication grooves to effectively ensure the service life of the pump.

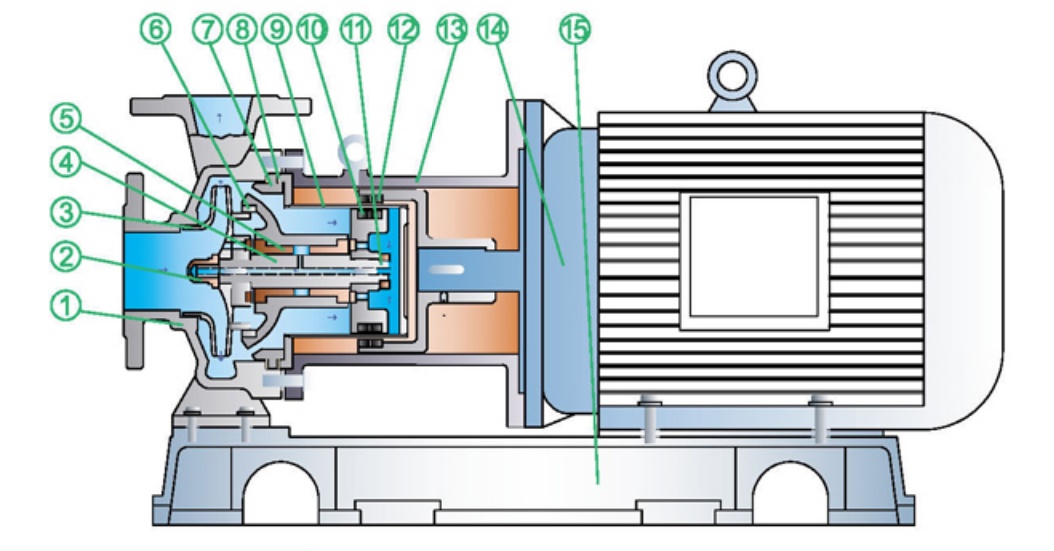

Structural diagram

| Part | Material | Part | Material | Part | Material |

| ①pump body | 304/316/316L | ⑥thrust collar | hard alloy | ⑪back nut | 304/316/316L |

| ②impeller nut | 304/316/316L | ⑦pump cover | 304/316/316L | ⑫out magnet | permanent magnet /HT200 |

| ③impeller | 304/316/316L | ⑧gasket | PTFE | ⑬connecting | HT200 |

| ④main shaft | 304/316/316L | ⑨distance sleeve | 304/316/316L | ⑭motor | As clients requested |

| ⑤shaft sleeve | GRAPHITE/SIC | ⑩inner magnet | permanent magnet /304/316/316L | ⑮base plate | HT200 |

Structural diagram

Performance Data

| Type | Rated power | Rated Flow | Rated Head | Voltage | Pump casing material | Suction |

| 25-20-125 | 2.2 | 2.5 | 20 | 380V | 304/316/316L | 25*20 |

| 25-20-160 | 3 | 2.5 | 32 | 380V | 304/316/316L | 25*20 |

| 25-20-200 | 5.5 | 2.5 | 50 | 380V | 304/316/316L | 25*20 |

| 25-20-250 | 11 | 2.5 | 80 | 380V | 304/316/316L | 25*20 |

| 32-20-125 | 2.2 | 3.2 | 20 | 380V | 304/316/316L | 32*20 |

| 32-20-160 | 3 | 3.2 | 32 | 380V | 304/316/316L | 32*20 |

| 32-20-200 | 5.5 | 3.2 | 50 | 380V | 304/316/316L | 32*20 |

| 32-20-250 | 11 | 3.2 | 80 | 380V | 304/316/316L | 32*20 |

| 40-25-125 | 2.2 | 6.3 | 20 | 380V | 304/316/316L | 40*25 |

| 40-25-160 | 3 | 6.3 | 32 | 380V | 304/316/316L | 40*25 |

| 40-25-200 | 5.5 | 6.3 | 50 | 380V | 304/316/316L | 40*25 |

| 40-25-250 | 11 | 6.3 | 80 | 380V | 304/316/316L | 40*25 |

| 50-32-125 | 3 | 12.5 | 20 | 380V | 304/316/316L | 50*32 |

| 50-32-160 | 4 | 12.5 | 32 | 380V | 304/316/316L | 50*32 |

| 50-32-200 | 7.5 | 12.5 | 50 | 380V | 304/316/316L | 50*32 |

| 50-32-250 | 15 | 12.5 | 80 | 380V | 304/316/316L | 50*32 |

| 65-50-125 | 4 | 25 | 20 | 380V | 304/316/316L | 65*50 |

| 65-50-160 | 7.5 | 25 | 32 | 380V | 304/316/316L | 65*50 |

| 65-40-200 | 15 | 25 | 50 | 380V | 304/316/316L | 65*40 |

| 65-40-250 | 18.5 | 25 | 80 | 380V | 304/316/316L | 65*40 |

| 80-65-125 | 7.5 | 50 | 20 | 380V | 304/316/316L | 80*65 |

| 80-65-160 | 15 | 50 | 32 | 380V | 304/316/316L | 80*65 |

| 80-50-200 | 18.5 | 50 | 50 | 380V | 304/316/316L | 80*50 |

| 100-80-125 | 15 | 100 | 20 | 380V | 304/316/316L | 100*80 |

| 100-80-160 | 18.5 | 100 | 32 | 380V | 304/316/316L | 100*80 |

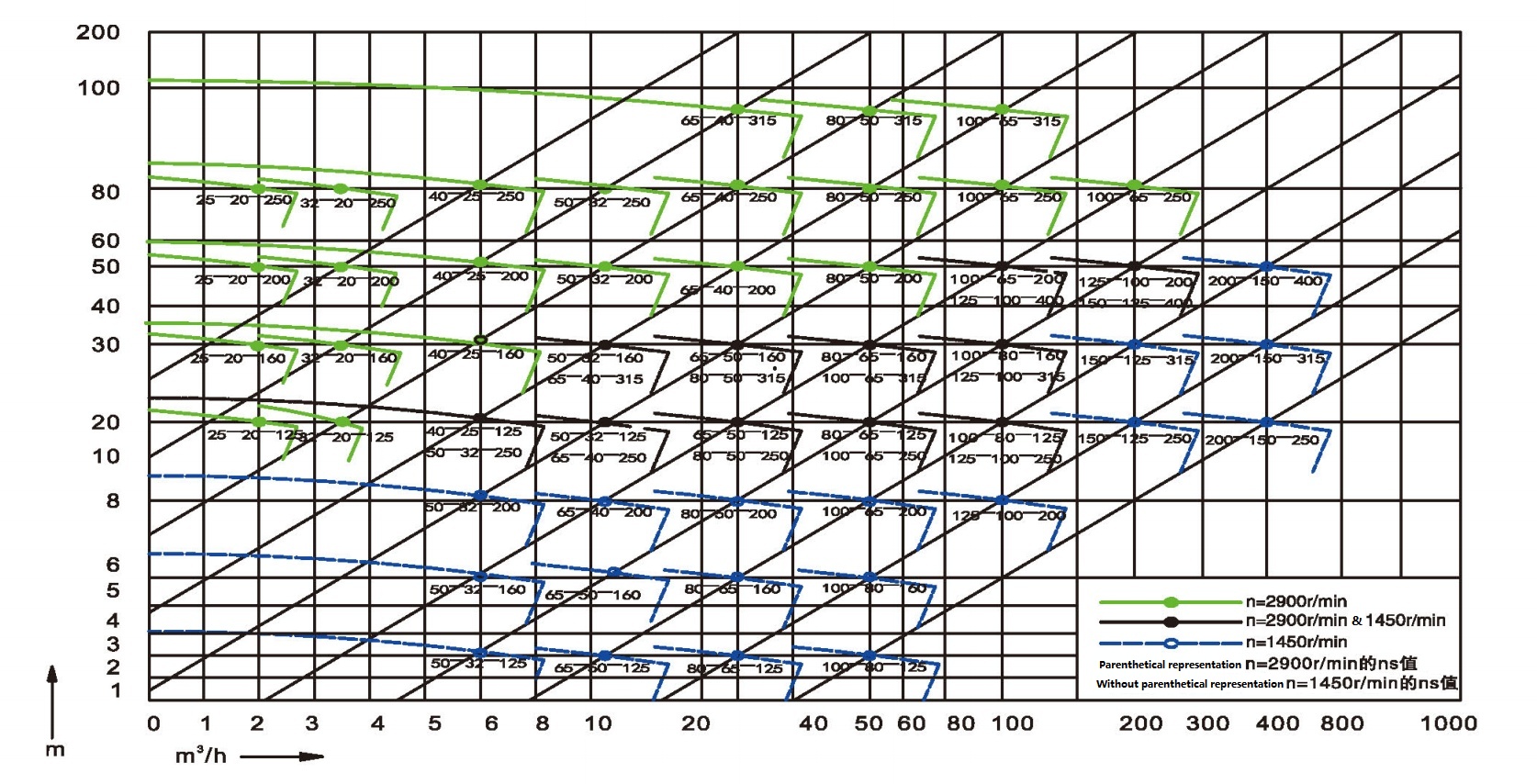

Performance range

Design pressure: 1.6 ~ 6.3MPa, Flow: 0.75 ~ 460m³/h, Lift: 5 ~ 125m, Power: 0.55 ~ 110KW

Applicable temperature: -60 ~ 300℃, new materials are adopted, and the temperature resistance can reach 450℃.

Product application

It is widely used to transport corrosive liquids in the production processes of petroleum, chemical industry, alkali making, smelting, rare earth, pesticide, dye, medicine, papermaking, electroplating, electrolysis and so on.

Others