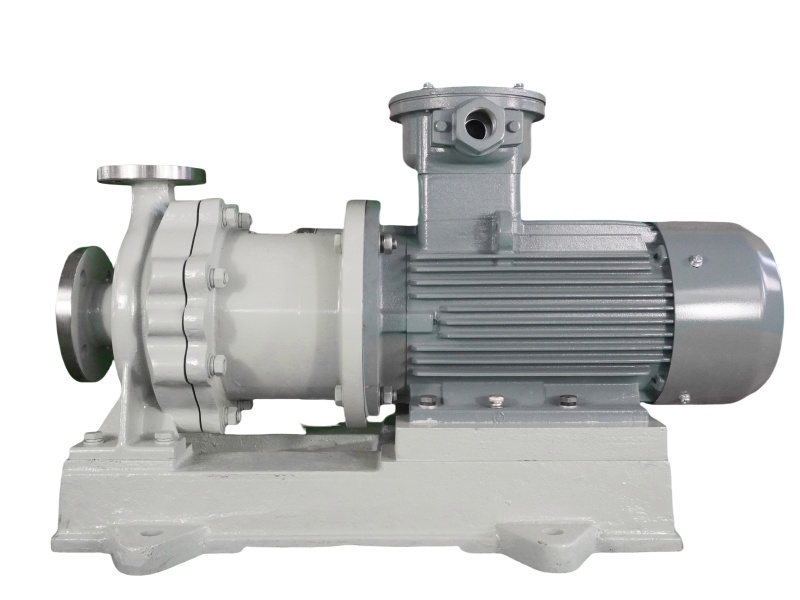

The TCH no - leakage stainless steel magnetic pump is an advanced industrial pump. It features a full - seal design, eliminating leakage. Made of stainless steel, it's corrosion - resistant. High - quality magnets ensure reliable magnetic drive, suitable for various industries.

MOQ:

1Package:

CustomziedColor:

CustomziedMaterial:

SteelWorking Temp:

-60 to 300 ℃,New material withstands temperatures up to 450°CWorking Pressure:

1.6 to 6.3 MPa

Product overview

TCH stainless steel magnetic force is upgraded and innovated on the basis of TC pump . It independently develops and designs the third generation of new industrial pump with full seal , no leakage and no pollution . It applies the principle of magnetomechanics and the medium is enclosed in the static isolation sleeve to realize the non - contact transmission of torque . The shaft seal device ( packing seal or mechanical seal ) of traditional centrifugal pump is cancelled , and the static seal is used to replace the dynamic seal to achieve full seal A new leakage free magnetic pump .

Product advantages

1. The magnet adopts ferrite magnet , Nd-Fe-B and samarium cobalt , which has good magnetism , high temperature resistance and no demagnetization ;

2. The shaft sleeve and sliding bearing are made of high wear- resistant silicon carbide, graphite, tetrafluoro and other materials, and equipped with lubrication grooves to effectively ensure the service life of the pump;

3. No leakage . All sealing points are sealed by closed static seal and driven by magnetic coupling. Nitrogen seal is not require, which is safe, economical and efficient.

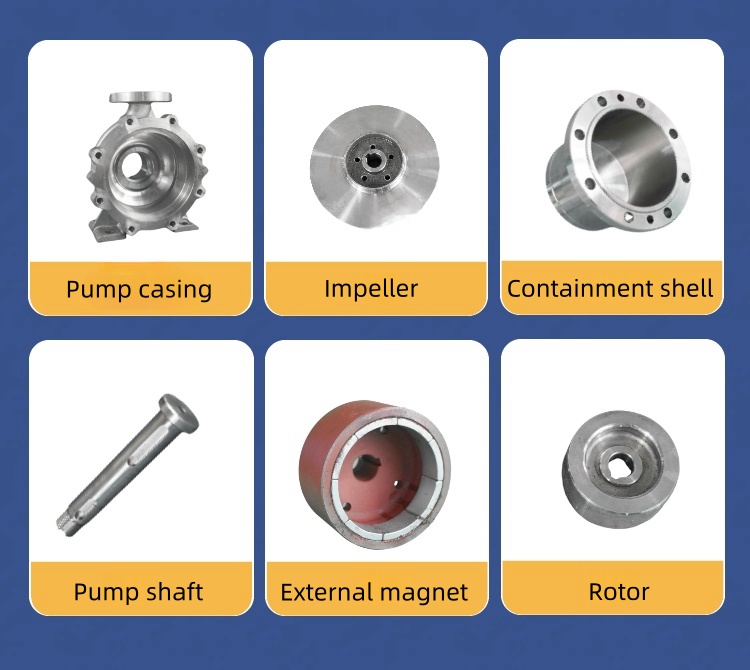

Material List

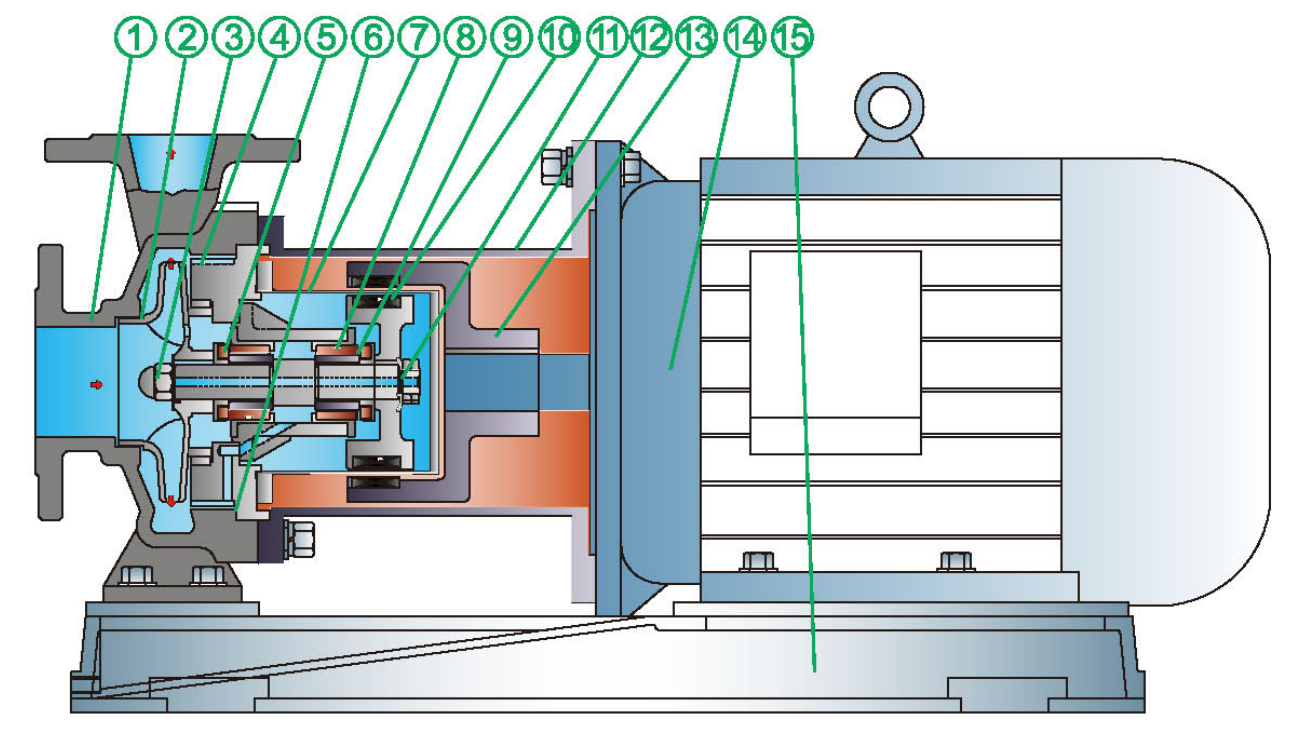

| Part | Material | Part | Material | Part | Material |

| ① Pump body | 304/316/316L | ⑥ Seal ring | Tetrafluoro | ⑪ Pump shaft | 304/316/316L/321 |

| ② Impeller | 304/316/316L | ⑦ Sealing sleeve | 316L/TA2/HC276 | ⑫ Bracket | Permenant magnet/HT200 |

| ③ Impeller nut |

304/316/316L | ⑧ Plain bearing assembly | Carbon fiber/SSIC/Cemented carbide | ⑬ Extemal magnet assembly | HT250/permenant magnet |

| ④ Pump cover | 304/316/316L | ⑨ Thrust disc assembly | Carbon fiber/SSIC/Cemented carbide | ⑭ ELectric machinery | Per clients requested |

| ⑤ Thrust disc assembly | Carbon fiber/SSIC/Cemented carbide | ⑩ Internal magnetic assembly | Permenant magnet/304/316/316L/321 | ⑮ Plate | HT200/A3/Channel steel |

Structural diagram

Performance Data

| Type | Rated power | Rated flow | Rated head | Voltage | Pump casing material | Suction |

| 25-20-125 | 1.5 | 2.5 | 20 | 380V | 304/316/316L | 25*20 |

| 25-20-160 | 2.2 | 2.5 | 32 | 380V | 304/316/316L | 25*20 |

| 25-20-200 | 5.5 | 2.5 | 50 | 380V | 304/316/316L | 25*20 |

| 25-20-250 | 11 | 2.5 | 80 | 380V | 304/316/316L | |

| 32-20-125 | 1.5 | 3.2 | 20 | 380V | 304/316/316L | 32*20 |

| 32-20-160 | 2.2 | 3.2 | 32 | 380V | 304/316/316L | 32*20 |

| 32-20-200 | 5.5 | 3.2 | 50 | 380V | 304/316/316L | 32*20 |

| 32-20-250 | 11 | 3.2 | 80 | 380V | 304/316/316L | 32*20 |

| 40-25-125 | 2.2 | 6.3 | 20 | 380V | 304/316/316L | 40*25 |

| 40-25-160 | 3 | 6.3 | 32 | 380V | 304/316/316L | 40*25 |

| 40-25-200 | 5.5 | 6.3 | 50 | 380V | 304/316/316L | 40*25 |

| 40-25-250 | 15 | 6.3 | 80 | 380V | 304/316/316L | 40*25 |

| 40-25-315 | 6.3 | 125 | 380V | 304/316/316L | 40*25 | |

| 50-32-125 | 3 | 12.5 | 20 | 380V | 304/316/316L | 50*32 |

| 50-32-160 | 4 | 12.5 | 32 | 380V | 304/316/316L | 50*32 |

| 50-32-200 | 7.5 | 12.5 | 50 | 380V | 304/316/316L | 50*32 |

| 50-32-250 | 15 | 12.5 | 80 | 380V | 304/316/316L | 50*32 |

| 50-32-315 | 12.5 | 125 | 380V | 304/316/316L | 50*32 | |

| 65-50-125 | 4 | 25 | 20 | 380V | 304/316/316L | 65*50 |

| 65-50-160 | 7.5 | 25 | 32 | 380V | 304/316/316L | 65*50 |

| 65-40-200 | 15 | 25 | 50 | 380V | 304/316/316L | 65*40 |

| 65-40-250 | 22 | 25 | 80 | 380V | 304/316/316L | 65*40 |

| 65-40-315 | 37 | 25 | 125 | 380V | 304/316/316L | 65*40 |

| 65-40-400 | 25 | 380V | 304/316/316L | 65*40 | ||

| 80-65-125 | 7.5 | 50 | 20 | 380V | 304/316/316L | 80*65 |

| 80-65-160 | 15 | 50 | 32 | 380V | 304/316/316L | 80*65 |

| 80-50-200 | 18.5 | 50 | 50 | 380V | 304/316/316L | 80*50 |

| 80-50-250 | 37 | 50 | 80 | 380V | 304/316/316L | 80*50 |

| 80-50-315 | 55 | 50 | 125 | 380V | 304/316/316L | 80*50 |

| 80-50-400 | 50 | 380V | 304/316/316L | 80*50 | ||

| 100-80-125 | 15 | 100 | 20 | 380V | 304/316/316L | 100*80 |

| 100-80-160 | 22 | 100 | 32 | 380V | 304/316/316L | 100*80 |

| 100-65-200 | 37 | 100 | 50 | 380V | 304/316/316L | 100*65 |

| 100-65-250 | 45 | 100 | 80 | 380V | 304/316/316L | 100*65 |

| 100-65-315 | 75 | 100 | 125 | 380V | 304/316/316L | 100*65 |

| 100-65-400 | 100 | 380V | 304/316/316L | 100*65 | ||

| 125-80-160 | 380V | 304/316/316L | 125*80 | |||

| 125-100-200 | 55 | 200 | 50 | 380V | 304/316/316L | 125*100 |

| 125-100-250 | 75 | 200 | 80 | 380V | 304/316/316L | 125*100 |

| 125-100-315 | 22 | 100 | 32 | 380V | 304/316/316L | 125*100 |

| 125-100-400 | 37 | 100 | 50 | 380V | 304/316/316L | 125*100 |

| 150-125-250 | 22 | 200 | 20 | 380V | 304/316/316L | 150*125 |

| 150-125-315 | 45 | 200 | 32 | 380V | 304/316/316L | 150*125 |

| 150-125-400 | 55 | 200 | 50 | 380V | 304/316/316L | 150*125 |

| 200-150-250 | 55 | 400 | 20 | 380V | 304/316/316L | 200*150 |

| 200-150-315 | 75 | 400 | 32 | 380V | 304/316/316L | 200*150 |

| 200-150-400 | 110 | 400 | 50 | 380V | 304/316/316L | 200*150 |

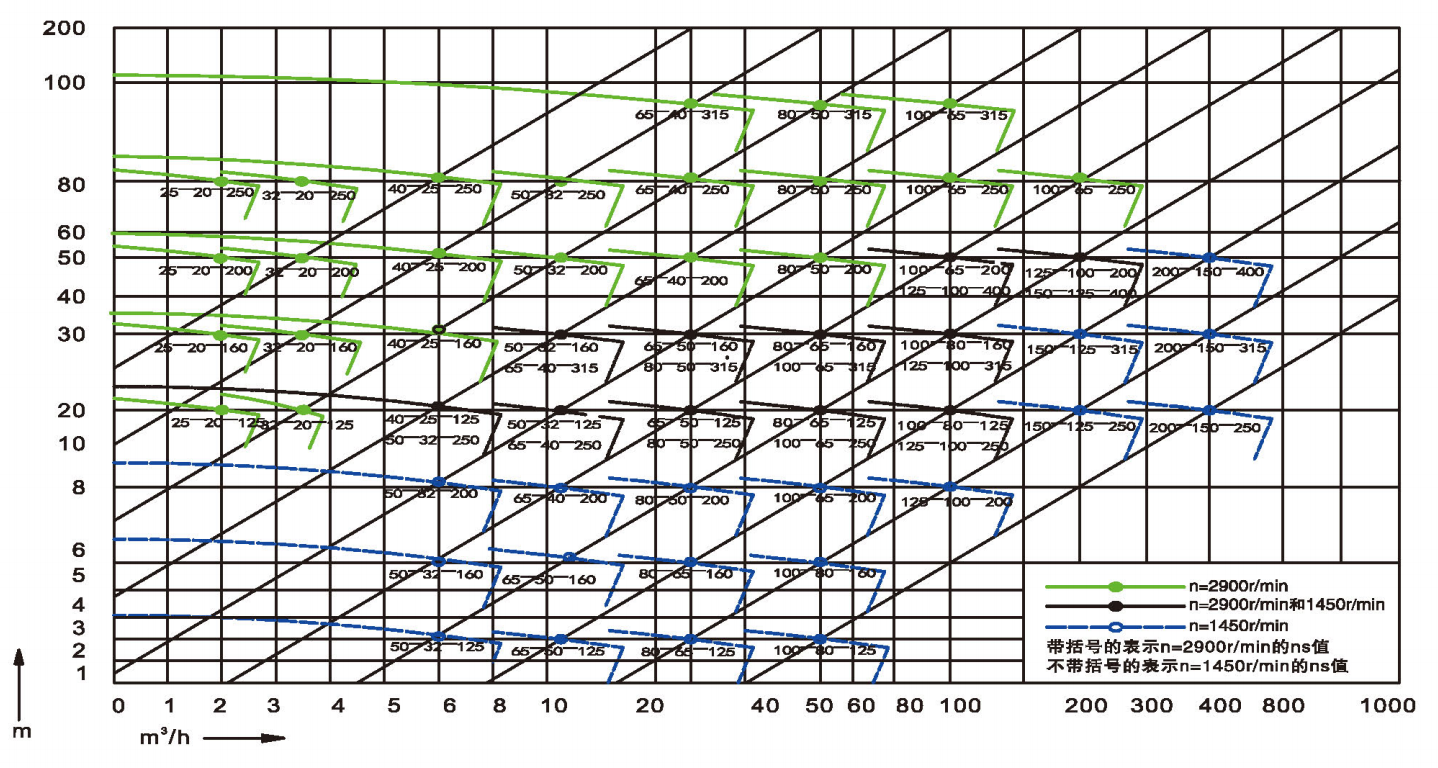

Performance range

Design pressure :1.6~6.3MPa, Flow :0.75~460m³/ h , Lift :5~125m, Power :0.55~110KW.

Applicable temperature :-60~300℃, new materials are adopted , and the temperature resistance can reach 450℃.

Product application

It is widely used in the transportation of corrosive liquids in the production processes of petroleum , chemical industry , alkali making , smelting , rare earth , pesticide , dye , medicine , papermaking , electroplating , electrolysis and so on , especially for the transportation of flammable , explosive , volatile , toxic , high temperature , strong alkali and organic solvents.

Others