The TCSF no - leakage lining fluorine magnetic pump. Lined with fluorine, it resists corrosion well. Magnetic drive ensures no leakage, ideal for chemical and industrial fluid transfer.

MOQ:

1Package:

CustomziedColor:

CustomziedMaterial:

FluoroplasticWorking Temp:

-20 to 120 ℃,Any concentration of acid-base mediumWorking Pressure:

1.6 MPa

Product overview

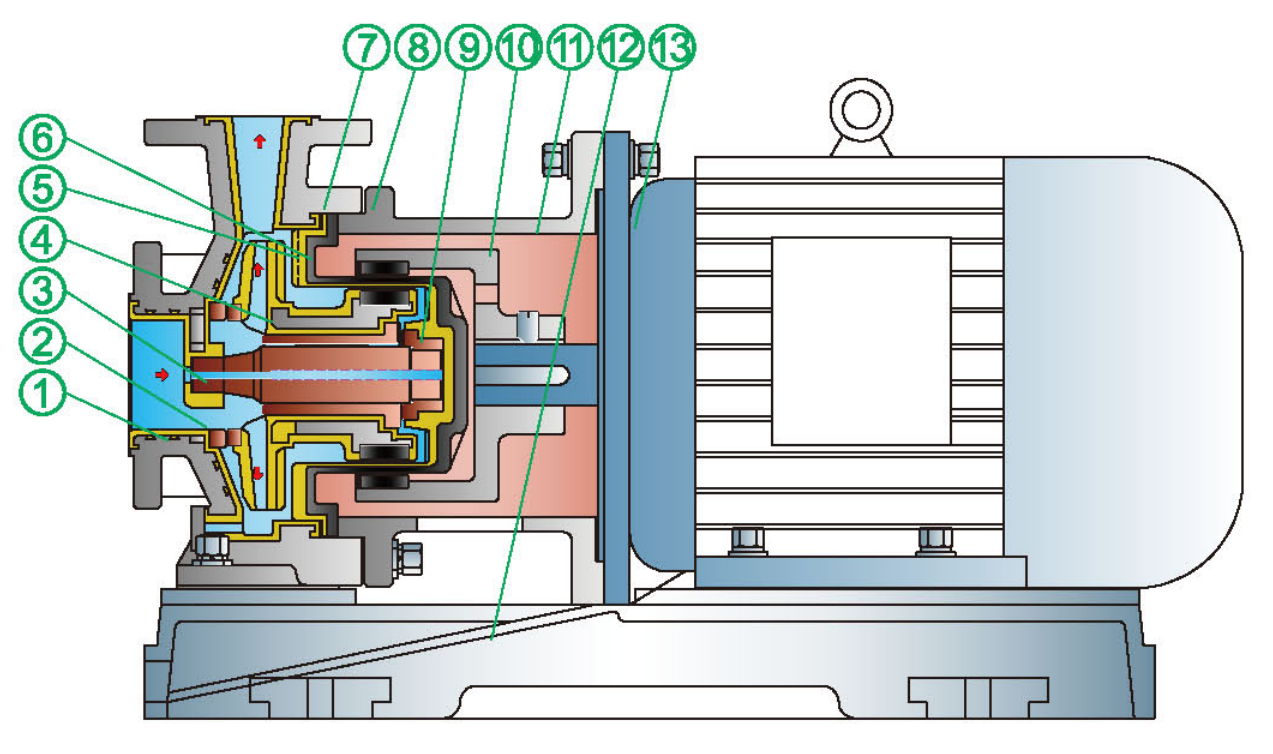

TCSF series fixed shaft magnetic pump is improved and optimized on the basis of the traditional magnetic pump , which changes the structure that the magnetic rotor drives the impeller to rotate through the pump shaft in the traditional magnetic pump structure . The structure is that the magnetic rotor directly drives the impeller to rotate , the shaft is fixed and does not rotate , and the shaft is only used as support .

Product advantages

1. The transmission efficiency and stability of the pump are improved , and the internal parts are reduced ;

2. The degree of generalization is higher . The magnetic transmission part of the pump is configured according to the power ;

3. Optimize the design of the magnetic circuit , so that the manufacturing cost of the pump is lower and the floor area is smaller .

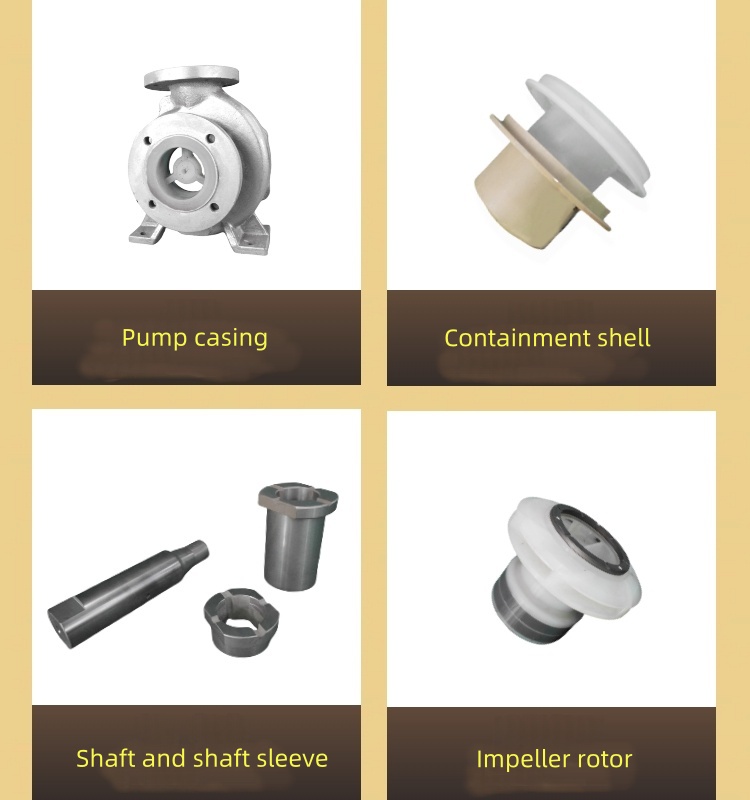

Material List

| Part | Material | Part | Material | Part | Material |

| ① Pump body | HT200/F46/PFA | ⑥ Reinforcing sleeve | PEEK | ⑪ Bracket | HT200/ZG |

| ② Pump body mouth ring | Filled PTFE/Silicon carbide | ⑦ Seal ring | Fluororubber/Teflon | ⑫ Base | HT200/Channel steel |

| ③ Pump shaft | Silicon carbide/Pressureless | ⑧ Axle sleeve | SIC/Pressureless | ⑬ Motor | Per client request |

| ④ Impeller assembly | 45# F46/PFA/Permanent magnet | ⑨ Spacer bearing | SIC/Pressureless | ||

| ⑤ Isolation sleeve | F46/PTFE | ⑩ Outer rotor assembly | HT250/Permanent magnet |

Structural diagram

Performance Data

| Type | Rated power | Rated flow | Rated head | Voltage | Pump casing material | Suction |

| 32-20-115F | 3.2 | 380V | F4/F46/F50 | 32*20 | ||

| 40-25-120F | 6.3 | 380V | F4/F46/F50 | 40*25 | ||

| 40-40-120F | 6.3 | 380V | F4/F46/F50 | 40*40 | ||

| 50-32-120F | 12.5 | 380V | F4/F46/F50 | 50*32 | ||

| 25-20-125 | 1.1 | 2.5 | 20 | 380V | F4/F46/F50 | 25*20 |

| 25-20-160 | 2.2 | 2.5 | 32 | 380V | F4/F46/F50 | 25*20 |

| 25-20-200 | 4 | 2.5 | 50 | 380V | F4/F46/F50 | 25*20 |

| 25-20-250 | 7.5 | 2.5 | 80 | 380V | F4/F46/F50 | 25*20 |

| 32-20-125 | 1.1 | 3.2 | 20 | 380V | F4/F46/F50 | 32*20 |

| 32-20-160 | 3 | 3.2 | 32 | 380V | F4/F46/F50 | 32*20 |

| 32-20-200 | 4 | 3.2 | 50 | 380V | F4/F46/F50 | 32*20 |

| 32-20-250 | 7.5 | 3.2 | 80 | 380V | F4/F46/F50 | 32*20 |

| 40-25-125 | 2.2 | 6.3 | 20 | 380V | F4/F46/F50 | 40*25 |

| 40-25-160 | 3 | 6.3 | 32 | 380V | F4/F46/F50 | 40*25 |

| 40-25-200 | 5.5 | 6.3 | 50 | 380V | F4/F46/F50 | 40*25 |

| 40-25-250 | 11 | 6.3 | 80 | 380V | F4/F46/F50 | 40*25 |

| 40-25-315 | 6.3 | 125 | 380V | F4/F46/F50 | 40*25 | |

| 50-32-125 | 3 | 12.5 | 20 | 380V | F4/F46/F50 | 50*32 |

| 50-32-160 | 4 | 12.5 | 32 | 380V | F4/F46/F50 | 50*32 |

| 50-32-200 | 7.5 | 12.5 | 50 | 380V | F4/F46/F50 | 50*32 |

| 50-32-250 | 11 | 12.5 | 80 | 380V | F4/F46/F50 | 50*32 |

| 50-32-315 | 12.5 | 125 | 380V | F4/F46/F50 | 50*32 | |

| 65-50-125 | 4 | 25 | 20 | 380V | F4/F46/F50 | 65*50 |

| 65-50-160 | 5.5 | 25 | 32 | 380V | F4/F46/F50 | 65*50 |

| 65-40-200 | 11 | 25 | 50 | 380V | F4/F46/F50 | 65*40 |

| 65-40-250 | 18.5 | 25 | 80 | 380V | F4/F46/F50 | 65*40 |

| 65-40-315 | 37 | 25 | 125 | 380V | F4/F46/F50 | 65*40 |

| 80-65-125 | 7.5 | 50 | 20 | 380V | F4/F46/F50 | 80*65 |

| 80-65-160 | 11 | 50 | 32 | 380V | F4/F46/F50 | 80*65 |

| 80-50-200 | 15 | 50 | 50 | 380V | F4/F46/F50 | 80*50 |

| 80-50-250 | 30 | 50 | 80 | 380V | F4/F46/F50 | 80*50 |

| 80-50-315 | 45 | 50 | 125 | 380V | F4/F46/F50 | 80*50 |

| 100-80-125 | 11 | 100 | 20 | 380V | F4/F46/F50 | 100*80 |

| 100-80-160 | 18.5 | 100 | 32 | 380V | F4/F46/F50 | 100*80 |

| 100-65-200 | 30 | 100 | 50 | 380V | F4/F46/F50 | 100*65 |

| 100-65-250 | 45 | 100 | 80 | 380V | F4/F46/F50 | 100*65 |

| 100-65-315 | 75 | 100 | 125 | 380V | F4/F46/F50 | 100*65 |

| 125-80-160 | 30 | 160 | 32 | 380V | F4/F46/F50 | 125*80 |

| 125-100-200 | 55 | 200 | 50 | 380V | F4/F46/F50 | 125*100 |

| 125-100-250 | 75 | 200 | 80 | 380V | F4/F46/F50 | 125*100 |

| 125-100-315 | 22 | 100 | 125 | 380V | F4/F46/F50 | 125*100 |

| 125-100-400 | 37 | 100 | 50 | 380V | F4/F46/F50 | 125*100 |

| 150-125-250 | 22 | 200 | 20 | 380V | F4/F46/F50 | 150*125 |

| 150-125-315 | 45 | 200 | 32 | 380V | F4/F46/F50 | 150*125 |

| 150-125-400 | 55 | 200 | 50 | 380V | F4/F46/F50 | 150*125 |

| 200-150-250 | 55 | 400 | 20 | 380V | F4/F46/F50 | 200*150 |

| 200-150-315 | 75 | 400 | 32 | 380V | F4/F46/F50 | 200*150 |

| 200-150-400 | 110 | 400 | 50 | 380V | F4/F46/F50 | 200*150 |

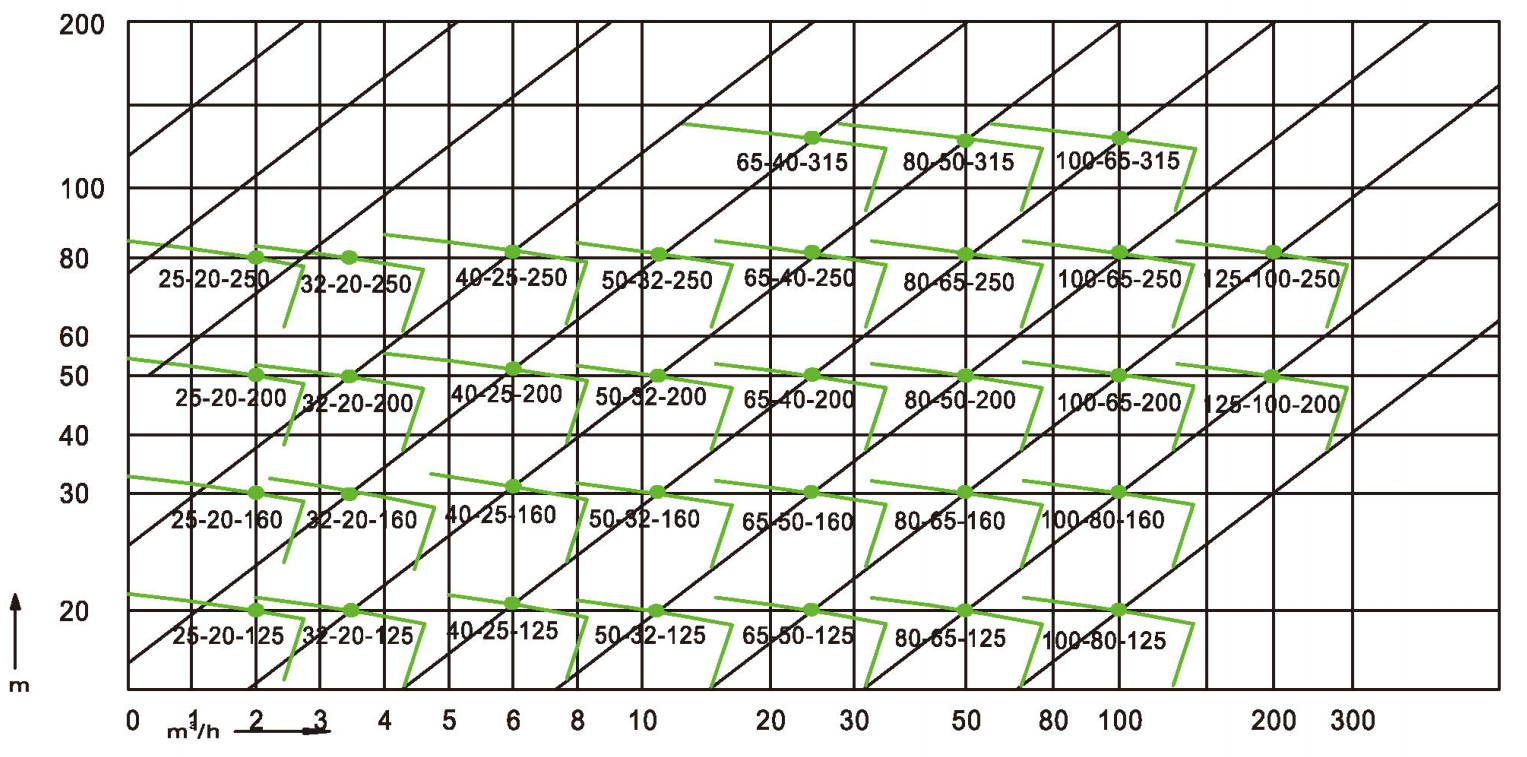

Performance range

Design pressure: 1.6 MPa, Flow: 0.75~460 m³/ h , Lift: 5~125 m, Power: 0.55~110 KW.

Applicable temperature :-20~120 ℃ , acid - base medium of any concentration.

Product application

It is widely used in petroleum , chemical industry , acid making , alkali making , smelting , rare earth , pesticide , dye , medicine , papermaking , electroplating , electrolysis , pickling , etc .

Others