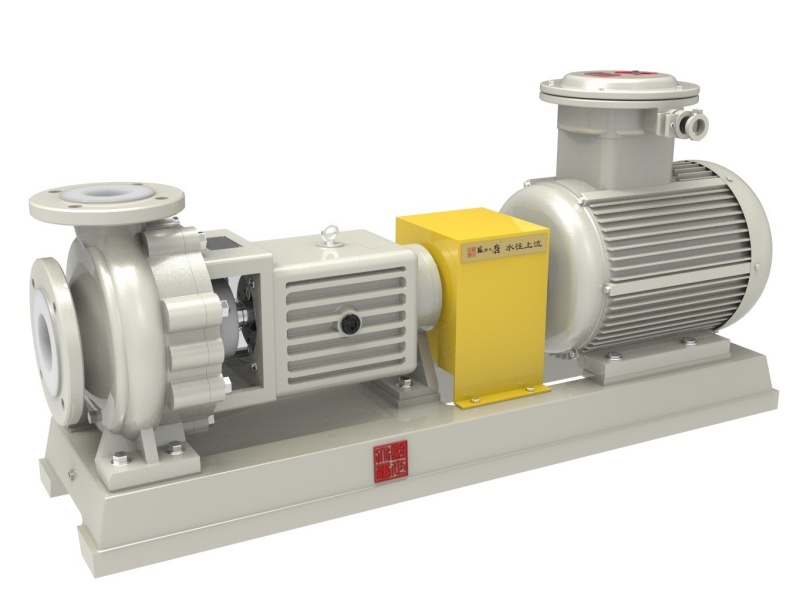

It features a fluorine lining for excellent corrosion resistance. High - quality materials ensure durability. Efficient centrifugal action enables stable fluid transportation, suitable for various chemical processes.

MOQ:

1Package:

CustomziedColor:

CustomizedMaterial:

Fluoroplastic alloy/SteelWorking Temp:

-20 to 120 ℃Working Pressure:

1.6 MPa

Product overview

The third generation improved product of THF fluorine lined centrifugal pump is designed and manufactured according to international standards and combined with the process design of non-metallic pump. It is suitable for long-term transportation of various corrosive media such as strong acid, alkali, salt and strong oxidant with arbitrary concentration. Its shell is lined with metal shell and all its overflow parts are made of plastic alloy.

Product advantages

1. THF fluorine lined centrifugal pump is designed and manufactured according to international standards and combined with the process of non-metallic pump. It has the advantages of corrosion resistance, high temperature resistance, no aging, high mechanical strength, high efficiency and energy saving.

2. The shaft seal adopts advanced external bellows mechanical seal, and the mechanical seal can be adjusted without disassembly. The sealing surface of the grinding can be equipped with silicon carbide, pressureless sintered silicon carbide, ceramics, tetrafluorocarbon, cemented carbide and other materials, so as to meet the requirements of conveying various media and ensure the service life of the mechanical seal.

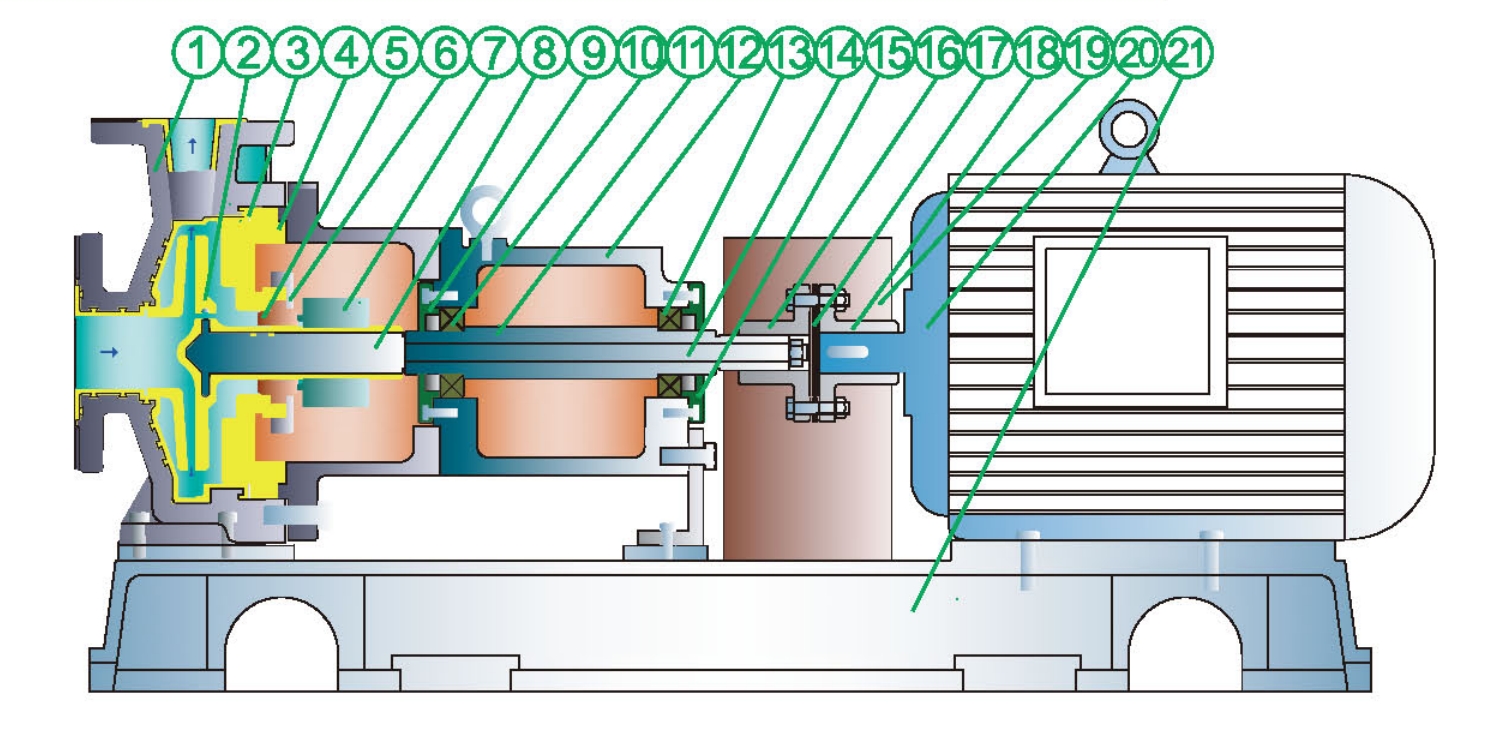

Structural diagram

Material List

| Part | Material | Part | Material | Part | Material |

| ①pump body | HT200/fluorine alloy lined | ⑧shaft | 304/316/316L | ⑮ gland of back bearing | HT200 |

| ②impeller | fluoroplastic alloy | ⑨bracket | HT200 | ⑯ pump coupling | 45# |

| ③gasket | fluorubber | ⑩gland of front bearing | HT200 | ⑰ diaphragm | 304 |

| ④pump cover | HT200/fluorine alloy lined | ⑪ frontbearing | rolling bearing | ⑱ electric coupling | 45# |

| ⑤static ring | silicon carbide/hard alloy | ⑫ bearing box | HT200 | ⑲ shield | 304 |

| ⑥seal gland | 304/316/316L | ⑬ back bearing | rolling bearing | ⑳ motor | as client request |

| ⑦dynamic ring | silicon carbide/hard alloy | ⑭ pull rod | 45# | ㉑plate | HT200 |

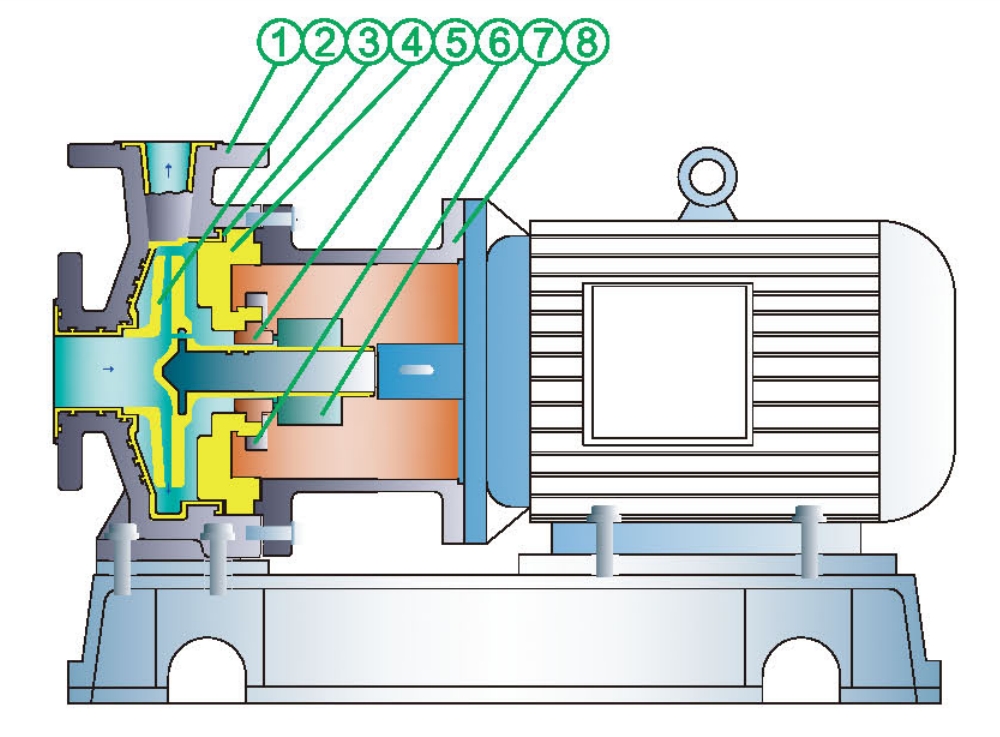

Structural diagram

Performance Data

| Model | Rated power | Rated flow | Rated head | Voltage | Pump body material | Inlet size |

| 25-20-125 | 1 | 2.5 | 20 | 380V | F46 | 25*20 |

| 25-20-160 | 2.2 | 2.5 | 32 | 380V | F46 | 25*20 |

| 25-20-200 | 4 | 2.5 | 50 | 380V | F46 | 25*20 |

| 25-20-250 | 11 | 2.5 | 80 | 380V | F46 | 25*20 |

| 32-20-125 | 1.5 | 3.2 | 20 | 380V | F46 | 32*20 |

| 32-20-160 | 2.2 | 3.2 | 32 | 380V | F46 | 32*20 |

| 32-20-200 | 4 | 3.2 | 50 | 380V | F46 | 32*20 |

| 32-20-250 | 11 | 3.2 | 80 | 380V | F46 | 32*20 |

| 40-25-125 | 1.5 | 6.3 | 20 | 380V | F46 | 40*25 |

| 40-25-160 | 2.2 | 6.3 | 32 | 380V | F46 | 40*25 |

| 40-25-200 | 5.5 | 6.3 | 50 | 380V | F46 | 40*25 |

| 40-25-250 | 11 | 6.3 | 80 | 380V | F46 | 40*25 |

| 40-25-315 | 6.3 | 125 | 380V | F46 | 40*25 | |

| 50-32-125 | 2.2 | 12.5 | 20 | 380V | F46 | 50*32 |

| 50-32-160 | 0.55 | 12.5 | 32 | 380V | F46 | 50*32 |

| 50-32-200 | 7.5 | 12.5 | 50 | 380V | F46 | 50*32 |

| 50-32-250 | 11 | 12.5 | 80 | 380V | F46 | 50*32 |

| 50-32-315 | 12.5 | 125 | 380V | F46 | 50*32 | |

| 65-50-125 | 3 | 25 | 20 | 380V | F46 | 65*50 |

| 65-50-160 | 5.5 | 25 | 32 | 380V | F46 | 65*50 |

| 65-40-200 | 11 | 25 | 50 | 380V | F46 | 65*50 |

| 65-40-250 | 18.5 | 25 | 80 | 380V | F46 | 65*50 |

| 65-40-315 | 30 | 25 | 125 | 380V | F46 | 80*65 |

| 80-65-125 | 5.5 | 50 | 20 | 380V | F46 | 80*65 |

| 80-65-160 | 11 | 50 | 32 | 380V | F46 | 80*65 |

| 80-50-200 | 15 | 50 | 50 | 380V | F46 | 80*50 |

| 80-50-250 | 30 | 50 | 80 | 380V | F46 | 80*50 |

| 80-50-315 | 45 | 50 | 125 | 380V | F46 | 80*50 |

| 100-80-125 | 11 | 100 | 20 | 380V | F46 | 100*80 |

| 100-80-160 | 15 | 100 | 32 | 380V | F46 | 100*65 |

| 100-65-200 | 30 | 100 | 50 | 380V | F46 | 100*65 |

| 100-65-250 | 45 | 100 | 80 | 380V | F46 | 100*65 |

| 100-65-315 | 75 | 100 | 125 | 380V | F46 | 100*65 |

| 125-80-160 | 55 | 160 | 32 | 380V | F46 | 125*80 |

| 125-100-200 | 55 | 200 | 50 | 380V | F46 | 125*100 |

| 125-100-250 | 75 | 200 | 80 | 380V | F46 | 125*100 |

| 125-100-315 | 18.5 | 200 | 125 | 380V | F46 | 125*100 |

| 125-100-400 | 37 | 200 | 50 | 380V | F46 | 125*100 |

| 150-125-250 | 22 | 200 | 20 | 380V | F46 | 150*125 |

| 150-125-315 | 45 | 200 | 32 | 380V | F46 | 150*125 |

| 150-125-400 | 75 | 200 | 50 | 380V | F46 | 150*125 |

| 200-150-250 | 45 | 400 | 20 | 380V | F46 | 200*150 |

| 200-150-315 | 75 | 400 | 32 | 380V | F46 | 200*150 |

| 200-150-400 | 110 | 400 | 50 | 380V | F46 | 200*150 |

| 250-200-250 | 160 | 800 | 50 | 380V | F46 | 250*200 |

| 250-200-315 | 110 | 800 | 32 | 380V | F46 | 250*200 |

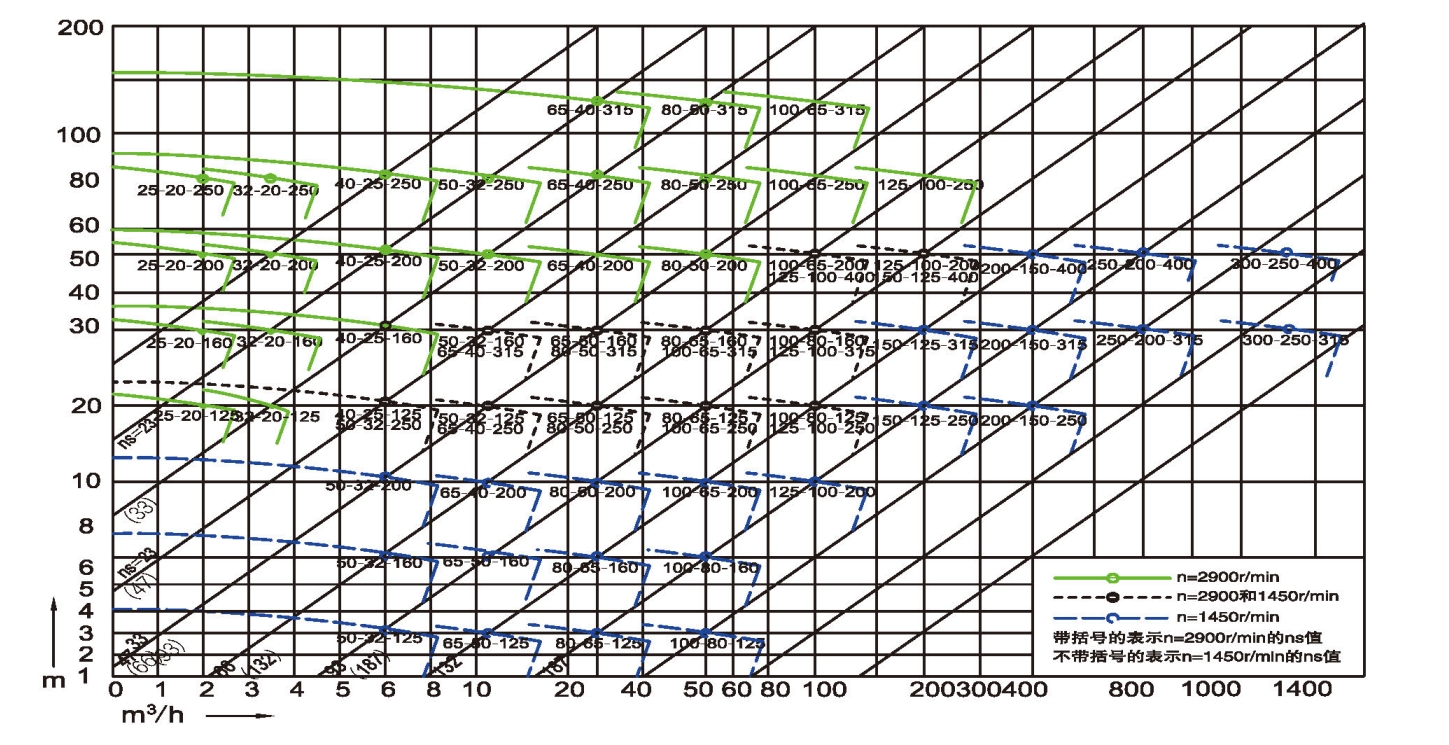

Performance range

Design pressure: 1.6MPa,

Flow rate: 0.75 ~1550m³/h,

Head: 3~125m,

Power: 1.1~ 400kw.

Applicable temperature: -20~120℃, using new materials resistant to temperature up to 180℃.

Product application