The THZWF fluorine axial flow pump is a high - quality pump. It is designed for fluorine - related applications. With advanced technology, it has high efficiency and stable performance. The pump can handle fluorine - containing fluids well, ensuring accurate flow and head control. Corrosion - resistant materials are used, guaranteeing long - term operation and reliability in various industrial processes.

MOQ:

1Package:

CustomziedColor:

CustomziedMaterial:

SteelWorking Temp:

-30 to 150 ℃Working Pressure:

1.6 MPa

Product overview

THZWF fluorine lined axial flow pump is a new type of acid , high temperature , corrosion and wear - resistant axial flow pump independently developed and designed by our company . The pump has a wide range of applications , especially suitable for corrosive media with high solid content , strong acid and high temperature .

Product advantages

1. Our company makes a fluorine-lined axial flow pump following GB/T13008 and non-metallic pump process. It's a splint graphite type. With high-temperature, corrosion, wear resistance, high strength, efficiency and energy-saving, it can be used safely in -30℃-150℃ for a long time;

2. The flow passage parts like pump body, impeller etc. are made of PTFE, ETFE, PFA etc. for different conditions.

3. The pump's seal is a cartridge-type double-face mechanical seal, high - temp, corrosion - and wear - resistant. It can transport media with particles/crystals. Api682-standard sealing arrangement and flushing scheme are configurable.

4. The moving and static rings of the mechanical seal are made of crystalline silicon carbide or HC276 alloy. These materials have high strength, wear resistance, toughness and corrosion resistance, effectively prolonging the pump's service life.

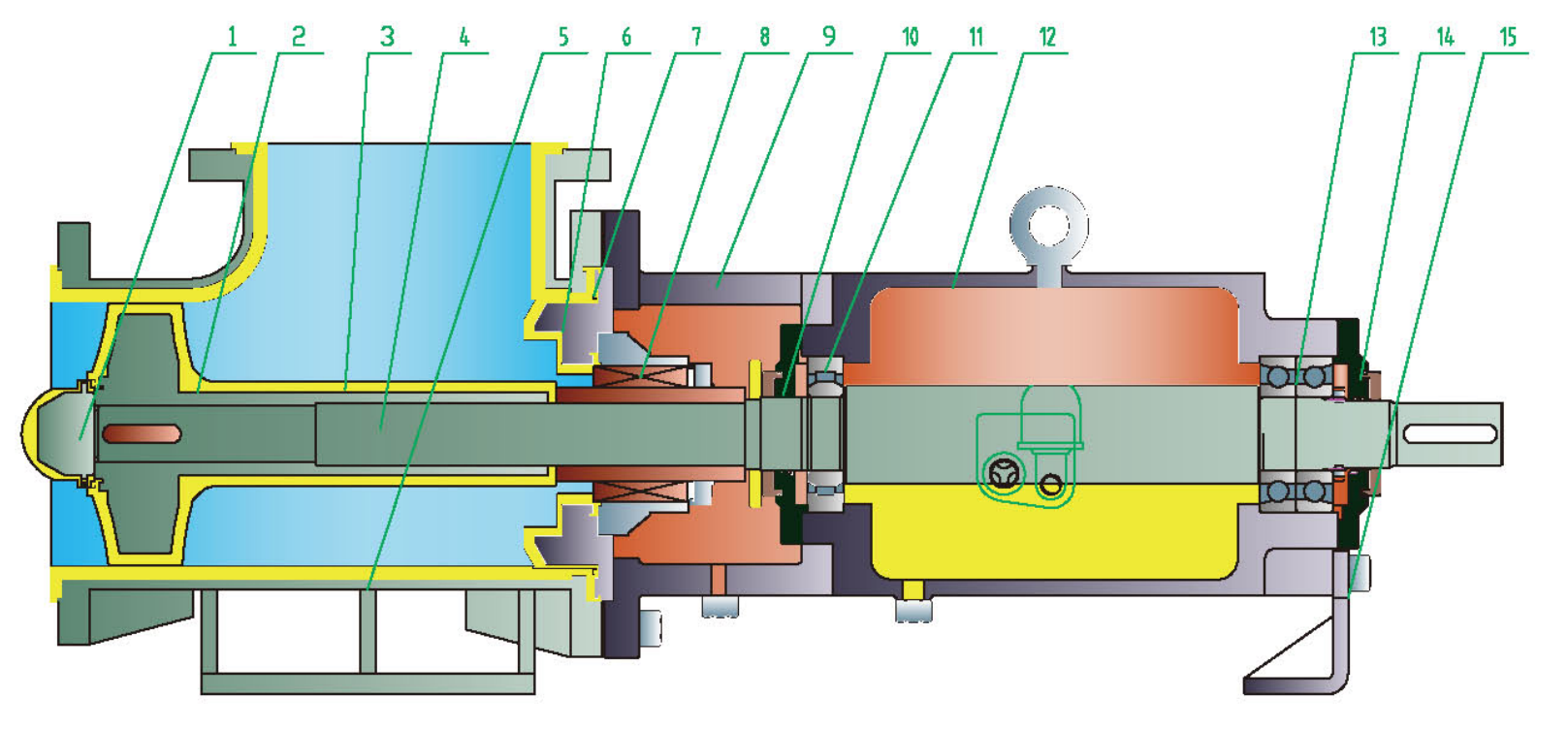

Material List

| Part | Material | Part | Material | Part | Material |

| ① Impeller nut | Steel lined fluoroplastic/ PFA | ⑥ Pump cover | Steel lined fluoroplastic/ PFA | ⑪ Front bearing | Gcr15 |

| ② Impeller | Steel lined fluoroplastic/ PFA | ⑦ Seal ring | Perfluoroether/PTFE nng | ⑫ Bearing box | HT200/ZG |

| ③ Axle sleeve | Steel lined fluoroplastic/ PFA | ⑧ Mechanical seal | Containerized water flushing machinery | ⑬ Rear bearing | Gcr15 |

| ④ Pump shaft | 45# steel quenching and tempering | ⑨ Backet | HT200/ZG | ⑭ Rear axle pressure cover | A3/ZG |

| ⑤ Pump body | Steel lined fluoroplastic/ PFA | ⑩ Front axle pressure cover | A3/ZG | ⑮ Support board | A3/ZG |

Structural diagram

Performance range

Design pressure :1.6MPa; Caliber :250~1000mm; Flow :300~12000m³/ h ; Lift :3~5m; Power :7.5~250kw;

Applicable temperature :-30℃~150℃.

Product application

Suitable for diaphragm caustic soda , phosphoric acid , vacuum salt making , calcium lactate , aluminum oxide , calcium chloride , ammonium chloride , sodium chlorate , sugar making , molten salt , papermaking, wastewater, etc. Especially suitable for high temperature hydrochloric acid , high temperature sulfuric acid , high temperature mixed acid and strong acid high temperature medium.

Others